Hydraulic Cutter for Difficult to Reach Decommissioning Projects

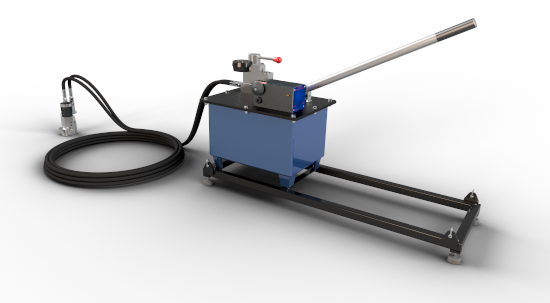

Allspeeds has developed its smallest hydraulic cutter so far for nuclear decommissioning projects. Designed to operate in a confined space, the WCO10 cutter, just 6” in height, can be used to cut 8mm wire rope. The cutter can be activated remotely by a 10K psi Tangye Hydrapak pump, also supplied by Allspeeds.

The hydraulically operated, Allspeeds cutting tool is operator independent – an important consideration in radiation exposure areas. Time spent in the area is reduced drastically as the cutter is positioned and activated, after which the engineer can retreat to a safe distance, significantly reducing radiation dosage.

The WCO10 cutter uses a cold cutting process whereby minimal heat is generated. Importantly, no swarf is produced. With conventional cutting methods, there is always a risk of airborne contamination that can be difficult to control and contain. Moreover, they often require the presence of the engineer during cutting, for example, using an angle grinder pressure must be applied to force the blade into the cut.

Allspeeds cutter applications in nuclear decommissioning range from removal of steel infrastructure to steel and plastic pipes. In high radiation environments, the tool’s blade and anvil can be replaced using remote manipulation.

For more information on Allspeeds’ range of cutters for nuclear projects visit the Nuclear Decommissioning page or call +44 (0)1254 615100 and email: info@allspeeds.co.uk